LARGE SELECTION OF

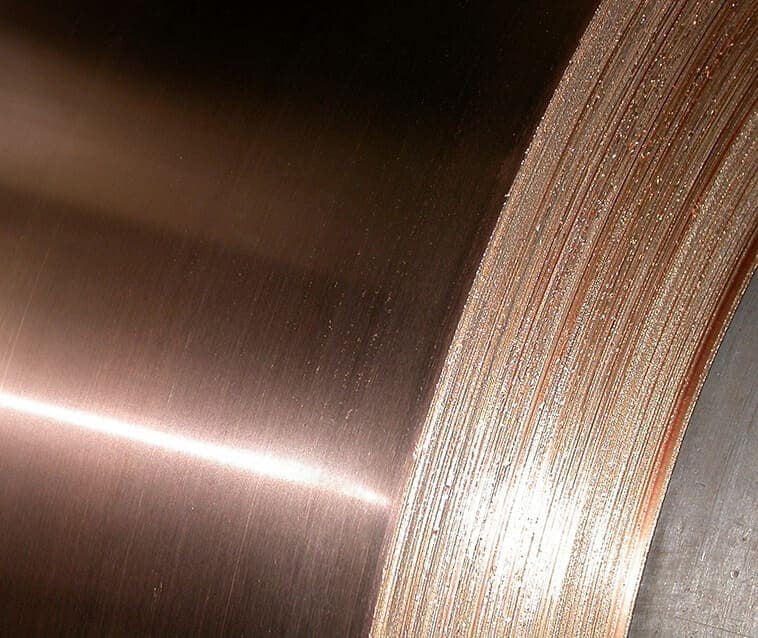

Bronze sheets and strips

We manufacture metal alloys with copper, including bronze. We offer a wide selection of bronze sheets and strips – in various alloy compositions and sizes. The type of bronze depends on the proportion of metal content, and above all on the amount of the second metal or semi-metal, e.g. aluminium, beryllium, tin, silicon or manganese. Our alloys, from which the bronze strip and bronze sheet are made, are manufactured according to the Polish PN and European PN-EN standards. Our portfolio includes tin bronzes B4 (CuSn4), B5 (CuSn5), B6 (CuSn6) and B8 (CuSn8) and silicon bronze BK31 (CuSa3MN1).

In addition to various types of bronze, we also manufacture high-quality brass and copper sheets and strips, Cupal (bimetal) sheets and others.

HIGH QUALITY

Abrasion resistant bronze

The customers buy our bronze strips and sheets to produce coins, springs or parts operating in sea water. The machine industry uses them to create precise components that must be extremely wear-resistant, while the electromechanical industry uses them to manufacture heat-resistant device parts. Thanks to its plastic properties, bronze is frequently used in foundry practice, e.g. as a material for monuments.

We manufacture bronze bands with a thickness ranging from 0.1 mm to 2 mm and a width ranging from 5 mm to 360 mm. Our bronze sheets have the following dimensions: thickness ranging from 0.2 mm to 30 mm, width ranging from 360 mm to 600 mm, length up to 2,000 mm. The sizes of bronze sheets depend on the type of alloy. Please contact our specialists to arrange all the details in a direct conversation.

SHEETS AND STRIPS PRODUCER

Bronze strip / Bronze sheet

Bronze strip / Bronze sheet

DIMENSIONS, STATES OF REINFORCEMENT

APPLICATIONS, INCL.

GRADES

| PN – 92/H-87050 | STANDARD DESIGNATION |

|||||

|---|---|---|---|---|---|---|

| PN-EN 1652 | DIN 17662 | ASTM B103, B97 | JIS H3110 | BS 2870 | ||

| CuSn4 | B4 | CuSn4 | CuSn4 | C51100 | C5111 | PB101 |

| – | – | CuSn5 | – | C51100 | C5102 | PB102 |

| CuSn6 | B6 | CuSn6 | CuSn6 | C51900 | C5191 | PB103 |

| CuSn8 | B8 | CuSn8 | CuSn8 | C52100 | C5212 | – |

| PN – 92/H-87060 | – | – | – | – | – | |

| CuSi3Mn1 | BK31 | – | – | C65500 | – | C5101 |

BRONZE STRIPS

| Thickness [mm] | Width [mm] | State of reinforcement | Inner coil diameters [mm] |

|---|---|---|---|

| 0,10 – 0,60 | 5 – 9 | r,pz | 260,360 |

| 10 – 360 | 100, 200, 300, 400, 500 | ||

| 0,61 – 2,00 | 20 – 360 | 400, 500 |

BRONZE SHEETS AND STRIPS

| Designation | Thickness [mm] | Width [mm] | Length [mm] | State of reinforcement |

|---|---|---|---|---|

| CuSn4, CuSn5, CuSn6, CuSn8, CuSi3Mn1 | 0,20 – 10,00 | max 360 | max 2000* | r, pz |

| CuSi3Mn1 | 5,00 – 30,00 | max 600 | pg | |

| * for thickness 2 mm – the max. length is 2,500 mm |

||||

Bronze is an alloy of copper with tin or another metal.

The melting point ranges from 940 to 1,084 degrees Celsius, while the density ranges from 7.5 to 9.3 g/cm³.

Bronzes have many advantages, including mainly durability (they are very resistant to weather conditions and corrosion). They are easy to form and show excellent friction-reducing properties.

Walcownia Metali Nieżelaznych “ŁABĘDY” S.A. manufactures such items as bronze sheets and bronze strips. The materials used in the production process include the so-called bronzes for plastic forming, from which, apart from sheets and strips, rods, wires and pipes are also manufactured.

However, the specific use of bronzes for metal forming depends on their composition. The range of compositions includes:

Do not hesitate to see also our portfolio of brass strips and sheets.

CALL, WRITE

Fast Contact

CONTACT