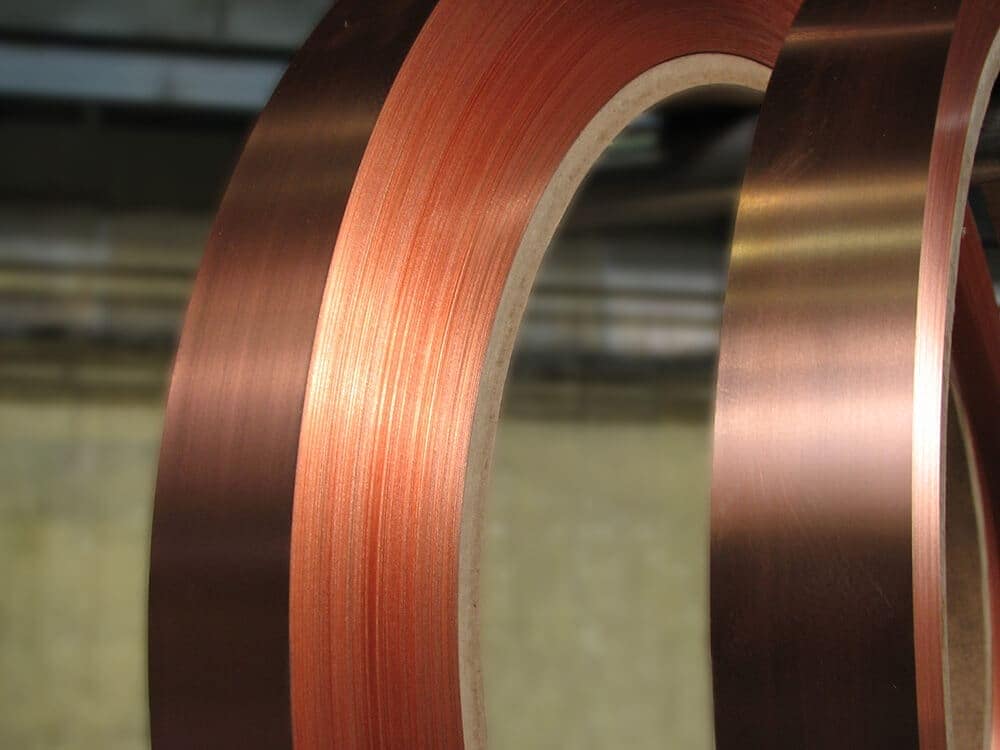

COPPER

The most valuable of metals

Copper is one of the most valuable metals, while the copper strips and copper sheets we manufacture are widely used in construction, electronics, automotive and other industries.

Our company offers a wide range of copper strips and sheets in a variety of sizes. We manufacture copper strips with a thickness ranging from 0.1 mm to 3 mm and a width ranging from 5 to 310 mm (on individual orders, we can deliver wider copper strips). We also sell copper in the form of copper strips and sheets – thickness ranges from 0.3 mm to 50 mm (up to 100 mm upon agreement), width ranges from 310 mm to 1,000 mm, length up to 2,500 mm.

THEY NEVER RUST

Roof strips and copper anodes

The major advantages of copper include high resistance to moisture, high plasticity and excellent electrical conductivity. It is an excellent material for roofing strips – it never rusts, but over time it develops patina and acquires a unique appearance. It is also used to carry out galvanic processes – our company manufactures high-quality copper anode used for such processes. The automotive industry uses copper products to manufacture radiators and engines. Copper is also a raw material frequently used by metalwork artists. An additional advantage of copper is the fact that as a raw material it is practically indestructible – it can be recycled many times without losing its basic properties. Our company uses worn copper products to manufacture new copper sheets and copper strips.

Copper is also an essential raw material for the production of many alloys that we also manufacture in our company. We offer i.a. bronze and brass strips and sheets in a variety of sizes. We manufacture many types of copper alloys developed according to Polish and European standards.

Please see our product portfolio.

SHEET AND STRIP MANUFACTURER

Copper Strip / Copper Sheet

Copper Strip / Copper Sheet

APPLICATION, incl.

DIMENSIONS, STATES OF REINFORCEMENT

* hot-rolled sheets with a width and length of 45 ÷ 100 mm are available upon prior agreement

GRADES

| PN-77/H-82120 | Standard Designation |

|||||||

|---|---|---|---|---|---|---|---|---|

| PN-EN 1652 | PN-EN 13599 | DIN 1787 | ASTM B152 | JIS H3100 | BS 2870 | |||

| Cu99,9 | M1E | Cu-ETP; Cu-FRTP |

Cu-ETP | E-Cu57; E-Cu58; SE-Cu |

C11000 | C1100 | C101 | |

| M1R | Cu-DLP | SW-Cu | C12000 | C1200 | – | |||

| M2R | Cu-DHP | SF-CU | SF-CU | C12200 | C1220 | C106 | ||

| Cu99,7 | M2G | – | – | – | – | – | ||

| Cu99,95 | – | – | Cu-HCP, Cu-PHC |

C10300 | ||||

COPPER STRIP

| Thickness [mm] | Width [mm] | State of reinforcement | Inner coil diameters [mm] |

|---|---|---|---|

| 0,10 – 0,11 | 5 – 9 | pz | 260, 360 |

| 10 – 310* | 100, 200, 300, 400, 500 | ||

| 0,12 – 0,60 | 5 – 9 | r, pz | 260, 360 |

| 10 – 310* | 100, 200, 300, 400, 500 | ||

| 0,61 – 3,00 | max 310* | r, pz | 400, 500 |

| * other widths available upon agreement |

|||

COPPER SHEETS AND PLATES

| Thickness [mm] | Width [mm] | Length [mm] | State of reinforcement |

|---|---|---|---|

| 0,30 – 2,00 | max 310* | max 2500 | r, pz |

| 2,20 – 10,00 2,20 – 10,00** 3,00 – 8,00 |

max 1000 max 650 max 1000 |

max 2200 max 2200 max 2000 |

|

| 10,10 – 100,00*** | max 1000 | max 2500 | pg |

| * other widths are available upon prior agreement ** for a thickness of 2,20 – 2,69 mm – sheets in a soft hardened state (without surface grinding); for a thickness 10 mm only soft hardened state *** hot-rolled sheets with a width and length of 45–100 mm are available upon prior agreement |

|||

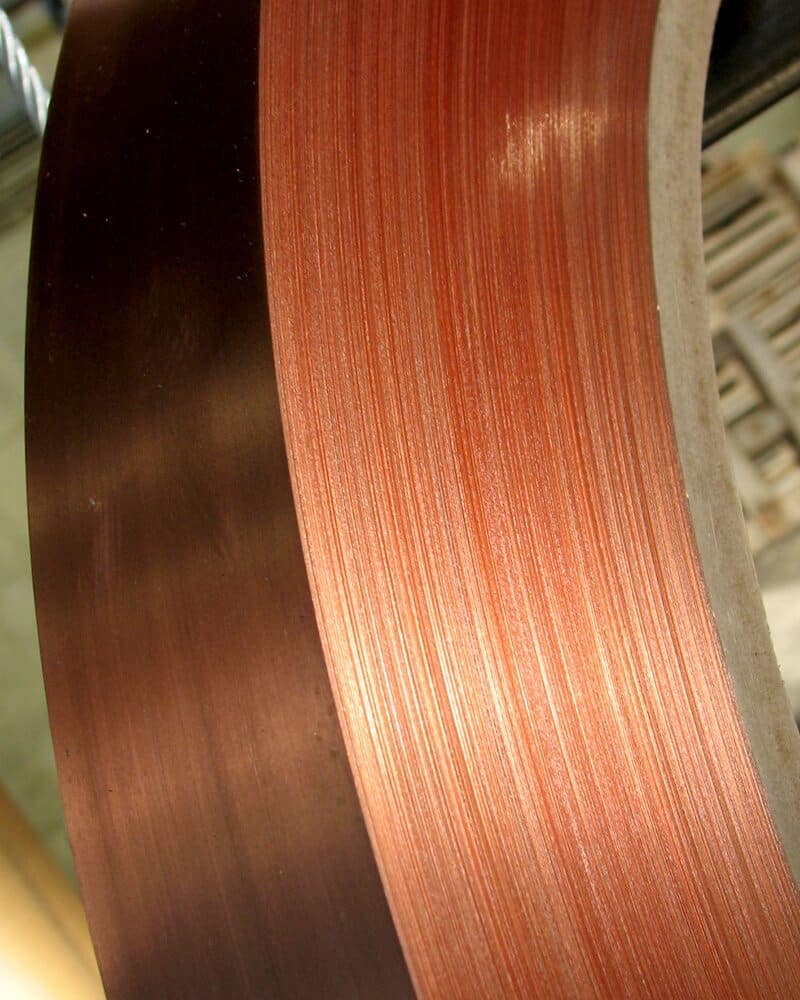

Copper is a chemical element belonging to the group of transition metals. It has a density of 8.96 g/cm³ and a melting point of 1,083 degrees Celsius. After purification and melting it transforms into a soft metal that is an excellent conductor of heat and electricity. High electrical conductivity and high thermal conductivity are largely due to the low hardness of this metal.

Our company manufactures copper products: copper sheets and strips. These items are widely used in many fields, including:

Why is it worth using copper sheets and strips? Because these products have many advantages that make them unmatched in some applications:

- Unrivalled tightness and durability, which can be most noticeable in roofing materials that can last up to 300 years.

- Resistance to weather conditions and moisture (it is fully water-tight).

- Copper can be freely formed, which can be especially appreciated in the case of roofs with an unusual shape.

- Copper is absolutely maintenance free.

- After a period of about 5–10 years – depending on the environment – it develops the so-called patina, i.e. green-grey copper oxide protecting it against corrosion. This additionally emphasises the unique appearance of copper components.

- Copper is an environmentally friendly metal because it can be recycled many times.

Please see also our portfolio of silver binders.

CALL, WRITE

Fast Contact

KONTAKT